for many oxygenated organic compounds, there are analogous derivatives in which sulfur replaces the oxygen atom. The derivatives are called “thiocompounds” (e.g., thioalcohols, thioethers, and thioaldehydes). Thiocompounds

corresponding to the alcohols (e.g., methanethiol) also are called “mercaptans” because they easily form mercury salts and have been used to treat mercury poisoning. Mercaptans tend to have strong, repugnant odors resembling skunk spray, rotten egg, or rotten cabbage. Low-molecular weight varieties of the compounds are used to odorize natural gas. Mercaptans are integral raw materials for many agricultural, pharmaceutical, and industrial products (e.g., pesticides and jet fuel additives). They are supplied primarily by companies such as OxyChem (NGO), ChevronPhillips, and Atofina, although waste products in the form of mercaptan and sulfide byproducts have long been available from pulp mills.

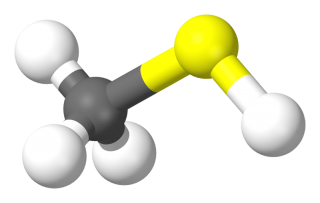

Methyl mercaptan (CH3SH) is toxic, as is hydrogen sulfide (H2S), but those of higher molecular weight (e.g., ethanediols, etc.) are not. In the presence of moisture they can be corrosive to various metals.

Chemical Properties of Mercaptan

H2S is an inorganic acid whose corrosive effects are well-known and irrelevant to this discussion except to show certain similarities. Conventional references regarding properties seem to differ slightly on the properties of mercaptans, but the following are some chemical characteristics of mercaptans of primary interest vs H2S:

• H2S—colorless gas, bp –60.33°C, solubility 0.33/100 parts H2O at 25°C1

• Methyl mercaptan—liquid or gas, bp 6°C, 2.3/100 parts H2O (MSOS G239)

• Ethyl mercaptan (C2H5SH)— liquid, bp 68°C, 1.5/100 parts H2O1

• Propanethiol-1 (C3H7SH)—liquid, bp 68°C, very slightly soluble1

• Butyl mercaptans (C4H9SH) have higher boiling points and are practically insoluble, whereas longer chain compounds are solids.

Hazards

TOXICITY

It is a well-known fact that H2S is highly poisonous (more so even than hydrocyanic acid [HCN]). The U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA) has established an acceptable limit of 10 ppm in the workplace, with a maximum level of 50 ppm allowed for 10 min if no other measurable exposure occurs. The U.S. Department of Health and Human Services’ National Institute for Occupational Safety and Health (NIOSH) recommends a maximum exposure of 10 ppm for 10 min. Most industrial deaths, however, occur very quickly from inadvertent exposure to much higher concentrations (e.g., 300 to 500 ppm). The problem is exacerbated by the fact that concentrations of ~115 ppm paralyze the olfactory nerves, making exposure to even higher toxic levels more likely despite the distinctive odor.

Methyl mercaptan is reportedly similar in nature although little is known about its health effects. There was a case in which a worker was exposed to very high levels of the compound when he opened and cleaned tanks; he developed anemia, went into a coma, and died ~1 month later. It is very possible that, like H2S, methyl mercaptan is selectively taken up by the brain stem, inhibiting respiration by blocking the enzymatic action of cytochrome oxidase. OSHA has set a permissible limit of 20 mg/m3 air for an 8-h workday in a 40-h week.

NIOSH recommends an occupational exposure limit of 1 mg/m3. The U.S. Environmental Protection Agency requires that discharges, spills, or accidental releases of 100 lb (45 kg) or more be reported.

OTHER HAZARDS

H2S forms stable, explosive mixtures with air over a wide range of concentrations. It explodes on contact with powerful oxidizing agents such as dichlorine oxide (Cl2O) and chlorine trifluoride (ClF3). Methyl mercaptan should be very similar, and even its high-molecular-weight derivatives are readily oxidizable and presumably combustible.

CORROSIVITY

Like H2S, methyl mercaptan should be noncorrosive in the anhydrous state but corrosive to certain metals in the presence of moisture—possibly because of hydrolysis and the release of sulfide ions.

ALUMINUM

These organic sulfides can be safely handled in aluminum storage tanks and piping.

STEEL

When anhydrous, mercaptans are noncorrosive to steel. The lower molecular- weight-compounds, however, such as those encountered in petroleum production and used to odorize natural gas, should be expected to cause sulfiderelated attack—sulfide stress cracking or hydrogen-affected cracking in susceptible steels in the presence of water—but this has not been observed in practical applications. High-molecular- weight mercaptans probably are

substantially noncorrosive, given their minimal water solubility.

Carbon steel process equipment gives decades of service in the manufacture of mercaptans and alkyl sulfides at up to 150°C. This is ascribed to the formation of a protective metal mercaptide film. Only in plant areas using alkanolamine acid gas removal systems is there any significant attack. This is a phenomenon well-known in the chemical processing industry.

STAINLESS STEELS

An austenitic stainless steel (SS) shows <2 mpy (51 µm/y) metal loss in 100% methyl mercaptan at ambient temperatures. By analogy with H2S, they probably will withstand wet mercaptans as well. Type 304L SS (UNS S30403) is used in equipment for selective absorption of heavy water from H2O via H2S extraction in those areas where steel is inadequate by virtue of physical removal of an otherwise protective iron sulfide (FeS) film.

Austenitic SS, however, is not resistant to mercaptans in the simultaneous presence of chlorides. Field tests in an 11-to-14% ammonium chloride (NH4Cl) brine at 90°C showed pitting of type 304 SS (UNS S30400) (nominally <1 mpy [25.4 µm/y] metal loss) in the presence of H2S and other mercaptans.

Type 316 SS (UNS S31600) did not experience attack under the same condition.

With mercaptans present in straight-run tower bottoms in the petroleum industry at ~185°C, type 304 SS showed severe pitting and crevice corrosion although the overall metal loss rate was only 0.5 mpy (12.7 µm/y). Severe pitting also was observed on type 316 SS—but with only 0.2 mpy (5.1 µm/y) general corrosion.

One must remember that the threshold temperature for stress corrosion cracking of 18-8 SS (UNS S31600) in sulfide/chloride environments may be lowered to ambient temperatures.

COPPER ALLOYS

Copper alloys typically are considered incompatible with mercaptans. It is probable, however, that the corrosivity of the mercaptan will vary both with moisture content and the particular alloy. It is common knowledge that “tarnishing” of copper hardware stems from traces of H2S in the atmosphere.

In a humid atmosphere in the simultaneous presence of H2S, however, copper is severely corroded—with the simultaneous formation of a thick, nonprotective copper sulfide (CuS) film. Yellow brass, however, can form a tightly adherent quasi-protective film.

There apparently is no reason for mercaptans to produce different corrosion characteristics, although published data 2 suggest rates of >50 mpy (1,270 µm/y) for copper, brass, and cupronickel in 100% mercaptan at ambient temperature.

The data distinguish neither humidity nor molecular weight of the mercaptans.

It would seem that a more detailed study might be made in the future.

NICKEL ALLOYS

The data also indicate a >50 mpy corrosion rate for nickel alloy 200 (UNS N02200) and Monel† alloy 400 (UNSN04400) in 100% mercaptans. It offers no data on higher alloys, however with or without chromium. Of course,

sulfur contamination makes nickel alloys subject to liquid metal embrittlement by the Ni-S eutectic if weld repairs are attempted without scrupulous cleaning.

MISCELLANEOUS METALS

Because divalent sulfur compounds like thiols (-SH) and sulfides (-S-) readily bond to heavy metal ions (silver, mercury, lead, and cadmium) and to iron, molybdenum, zinc, and copper, one should expect a potential for corrosion by mercaptans if moisture (e.g., relative humidity or aqueous phases) is present. Gold, platinum, and tantalum resist corrosion in such conditions.

Powerful oxidizing agents would convert these sulfides to sulfuric acid (H2SO4)-type compounds of different corrosion characteristics.

Conclusions

Plastics and elastomers can be affected by the organic component in mercaptans. Such complex interactions may be caused by the simultaneous presence of chlorides. The corrosion data published for wet and dry H2S should be broadly useful for this closely analogous environment (mercaptans)—at least for the lower-molecular-weight products. However, H2S really is a separate consideration and extrapolation of its data would lead to significant project costs because of overspecification of engineering requirements and controls.

References

1. Lange’s Handbook of Chemistry (New York, NY: McGraw-Hill Corp.).

2. N.E. Hamner, ed., Corrosion Data Survey, 5th and 6th ed. (Houston, TX: NACE, 1975).